Polysilicon sputtering target

Polysilicon sputtering target

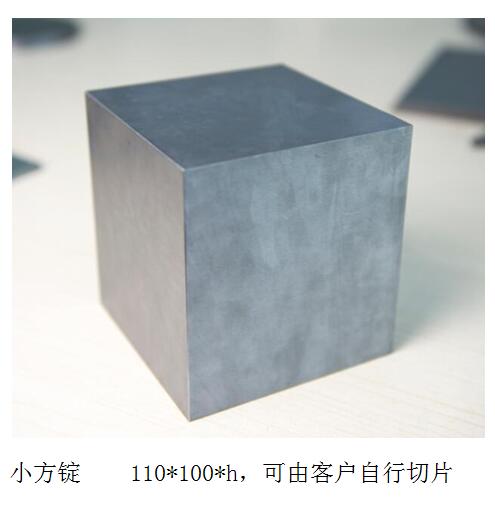

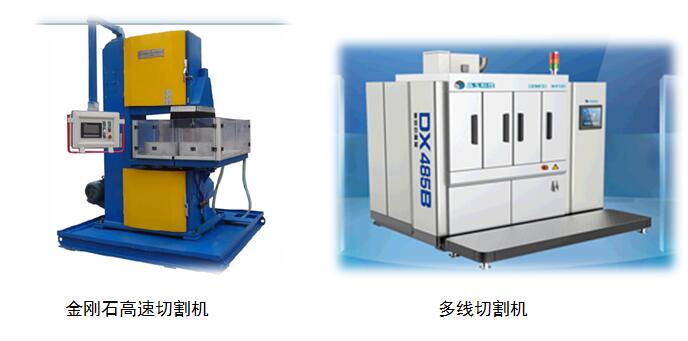

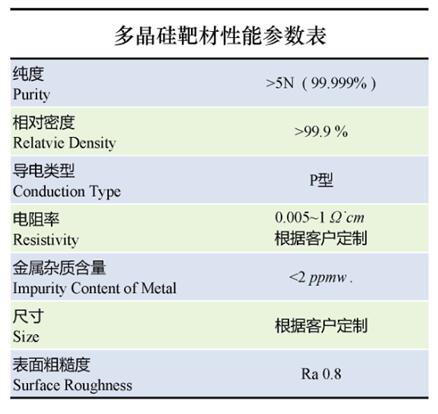

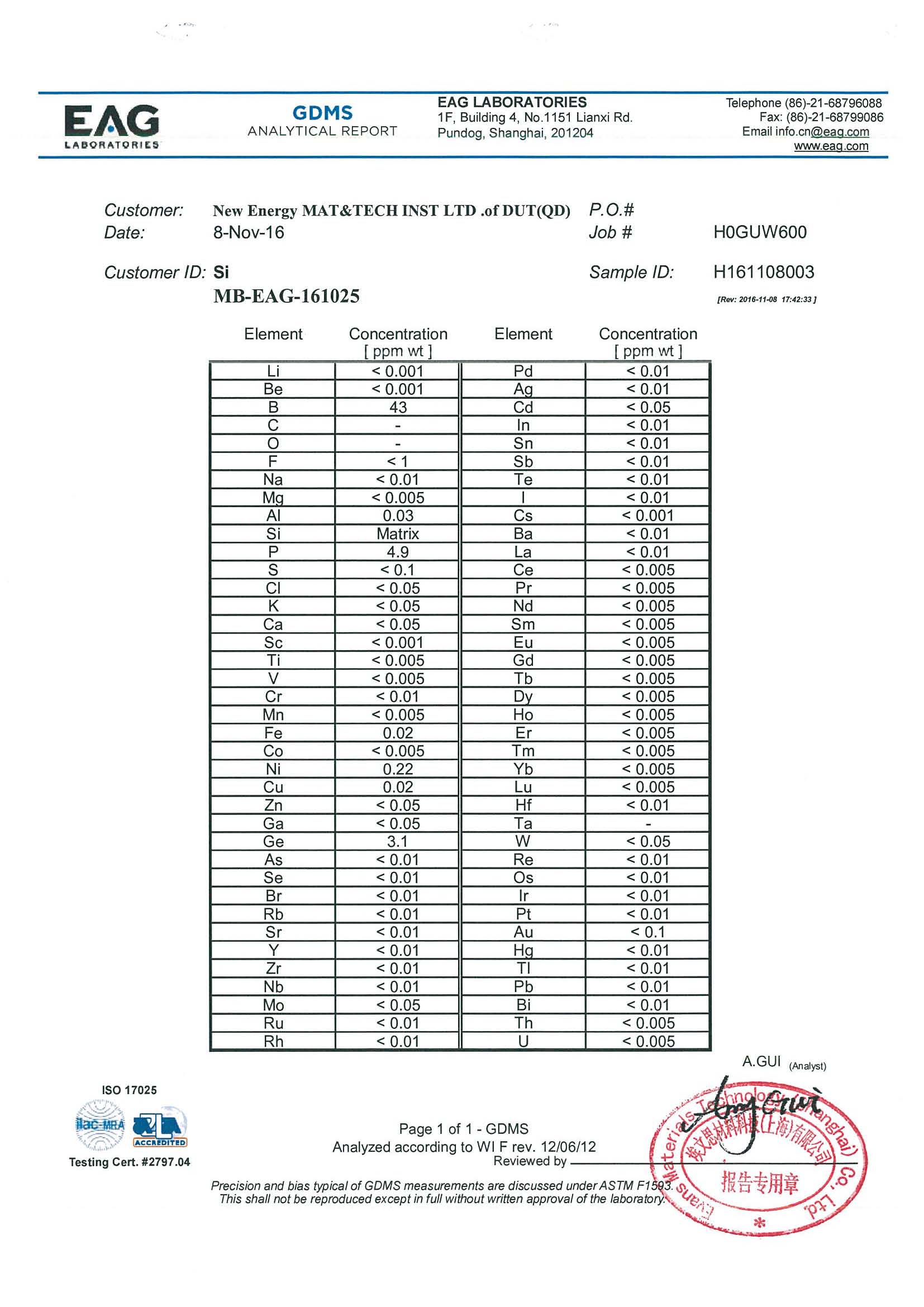

Polysilicon is an important sputtering target material. The preparation of SiO2 and other thin film layers by magnetron sputtering can make the matrix material with better optical, dielectric and corrosion resistance. It has been widely used in touch screen and optical industries. The silicon target material prepared by the long crystal process of the polysilicon ingot furnace of GT-Solar company in the United States has the characteristics of high purity, excellent electrical conductivity, uniform grain and so on. The maximum size of silicon material can reach 1m x 1m. In combination with advanced processing equipment and technology such as diamond band saw, diamond wire cutting, multi wire cutting and other advanced processing equipment, various target products of different sizes can be produced.

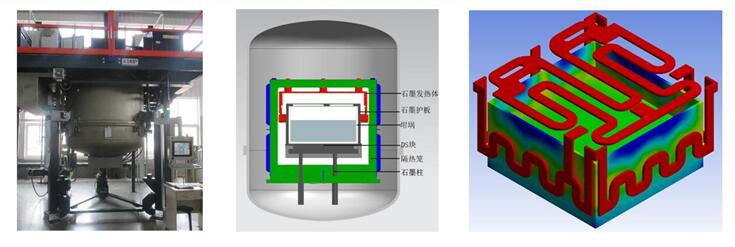

The casting long crystal process is to realize the directional solidification of liquid silicon from the bottom and gradually to the top by controlling the temperature of the heater in the heat field of the ingot furnace and the heat dissipation of the heat insulation material. The solidification of the liquid silicon is 0.8~1.2cm/h. At the same time, in the directional solidification process, the segregation effect of metal elements in the silicon material can be realized, and the purification of most metal elements can be realized, and the homogeneous polysilicon grain structure is formed.

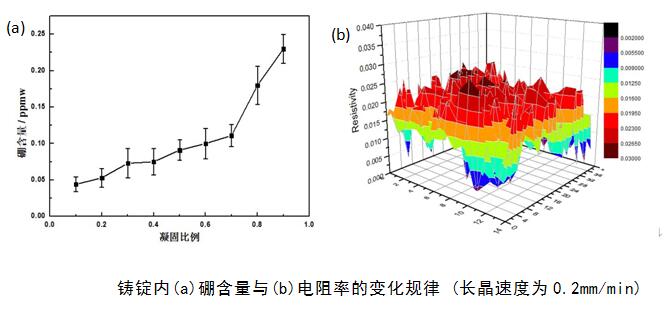

Casting polysilicon needs intentional doping in the production process. The purpose is to change the concentration of acceptor impurities in silicon melt. The main dopant of P cast polysilicon in the industry is silicon boron master alloy, of which boron content is about 0.025%. The doping level is determined by the target resistivity of the silicon wafer. The optimum resistivity is 0.02 ~0.05 Omega cm, and the corresponding boron concentration is about 2 * 1014cm-3. However, the segregation coefficient of boron in silicon is 0.8, which shows a certain segregation effect during the directional solidification, that is, the gradient distribution of boron in the vertical direction of the ingot, which leads to the gradual decrease of the resistivity from the bottom to the top of the ingot.

Through the screening of raw materials, the precise control of the long crystal process and the annealing process, the high purity, stable resistivity and uniform grain of the polysilicon target material are realized, and the perfect inspection and testing methods and the optimization of processing technology are carried out. The quality stability of the polysilicon sputtering target material has been controlled to the best and has been obtained. It has been widely recognized by the customers in the industry.

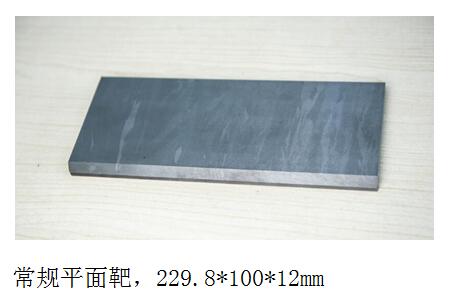

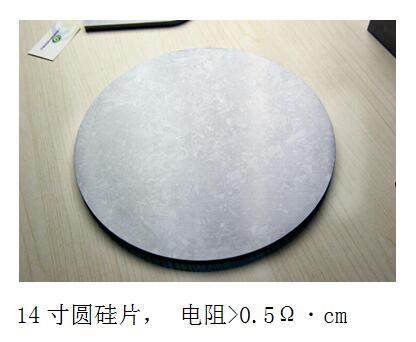

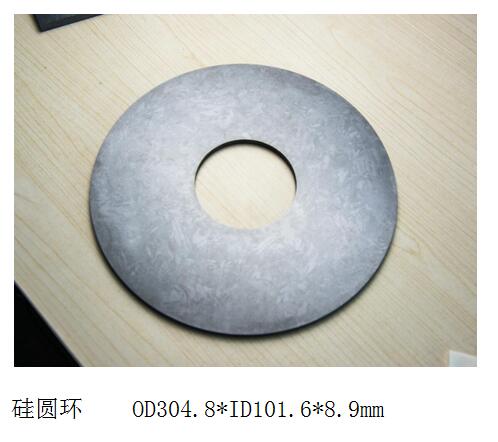

Product display: